TESTED TO INDUSTRY STANDARDS

Our case hardware (corners, latches etc.) is manufactured and tested to the highest industry standards. All hardware is attached to the cases using break-stem blind rivets. This ensures that in the event of damage in the field, the parts are easily drilled out and replaced, avoiding costly down-time.

RECESSED HARDWARE

The majority of recessed hardware consists of latches, handles, and various dishes or panels. The obvious benefit to recessed hardware is that it does not protrude from the case. This significantly reduces damage that can often occur when shipping by commercial carrier. Recessed hardware does take up a small amount of space inside the case which is unavoidable. For smaller cases, or cases that are not used in abusive situations, surface hardware may be a better choice.

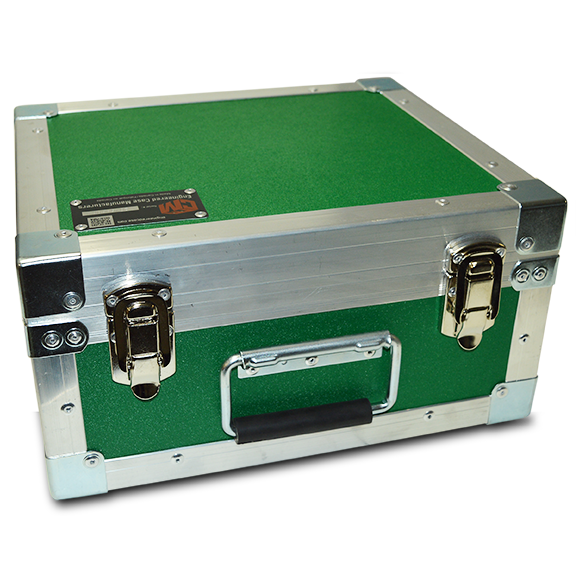

SURFACE HARDWARE

If you are purchasing a case but don’t plan on shipping it via commercial carrier (or at all), then specifying surface-mount hardware will result in substantial cost savings. While surface-mount hardware is functionally similar to recessed hardware, it is more vulnerable to damage.

Having the ability to select surface-mount hardware extends the range of options available to you. One of the advantages (besides cost) of using surface-mount hardware is that cases can be smaller. For example, in order to install a recessed handle on the side of a rack case, the minimum height needed would be 4″. That’s a 3 rack space (5.25″) minimum height. Using surface-mount hardware, this could be reduced to 2 rack spaces (3.5″).