EXCEPTIONALLY STRONG YET LIGHTWEIGHT

If weight is your primary concern, rigidized aluminum sheet is the case material of choice. With a tensile strength of 31,000 to 44,000 psi, Rigidized aluminum cases offer weight reductions of up to 35% over comparable laminate cases while maintaining an outstanding strength to weight ratio. At ECM we offer the choice of .063” material for ultimate strength and .050” material for further weight reduction.

AIRCRAFT GRADE, RIGIDIZED ALUMINUM SHEET

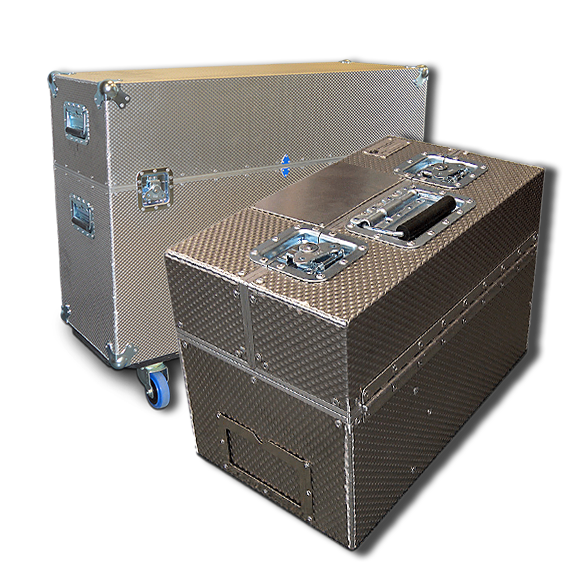

“Rigidized” refers to the patterning on the surface of an aluminum sheet, designed to provide rigidity, abrasion resistance and strength superior to plain aluminum sheet or drawn aluminum. Cases using this material are TIG-welded in our facility to the configuration and size specified.

Each sheet is made from 5052 aluminum alloy (the same alloy used to manufacture aircraft fuel tanks). Whatever your choice, both the .063” and .050” material are mated to our custom extrusions that guarantee outstanding structural rigidity.

We are ready to build, tell us more about your project

Each project is taken with the same care as we would put into our own.

MANY CUSTOMIZABLE OPTIONS

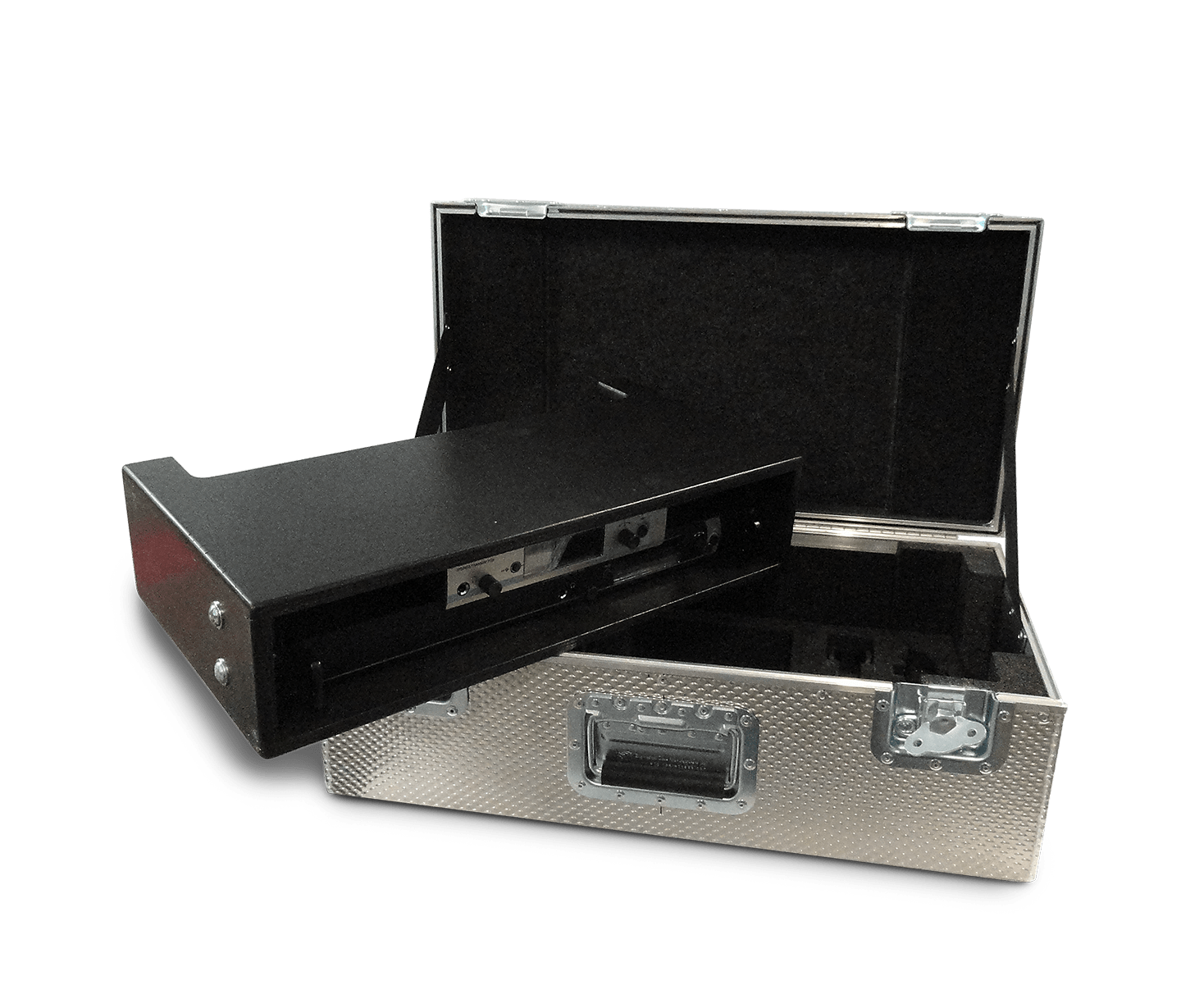

Your rigidized aluminum case can be customized to your requirements through the use of a wide range of hardware options. Recessed or collapsible pull handles, casters, and locking latches are but a few of the hardware choices. Aluminum cases can also be anodized or powder coated in a wide assortment of colours (see colour chart). And as always, we can provide a custom designed interior for your equipment.

AN ENVIRONMENTALLY RESPONSIBLE CHOICE

When you choose aluminum cases you are making an environmentally responsible choice. At the end of their useful life the aluminum in our cases can be recycled.

TYPICAL ALUMINUM CASE CONFIGURATIONS

| Heavy Duty | Medium Duty | |

|---|---|---|

| Panel Thickness | 0.063" | 0.050" |

| Hardware | Recessed | Surface or recessed |

| Foam | Etha | Etha or Polyurethane |

| Construction | Welded | Welded |